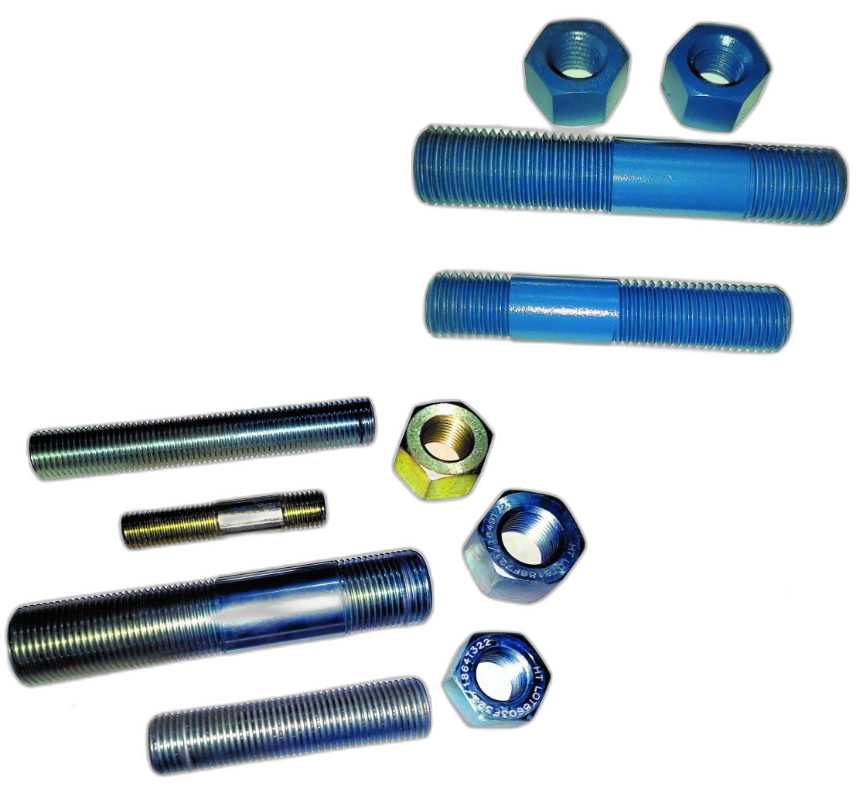

STUDS AND NUTS

- Products

- Piping and Flow Control

- Studs & Nuts

Studs and Nuts

Engineered for Strength and Reliability in Critical Connections

- Overview

Our Studs and Nuts are designed for high-strength, reliable connections in a variety of oilfield applications. Manufactured to meet the rigorous demands of the oil and gas industry, these components ensure the integrity of connections under high-pressure conditions.

Technical Specifications of Studs and Nuts

High-grade steel for maximum strength and corrosion resistance.

The API 20 E Bolting is manufactured in several material classes:

- ASTM Grades

- ASTMA193-B7, B7M

- ASTM A194-2H, 7, 2HM, 7M

- ASTM A320 - Grades L7, L7M, L43

Bolting Specification Level (BSL)

- BSL-1

- BSL-2

Available in a range of sizes to suit diverse operational needs.

- Machined studs

- Machined bolts, screws, and nuts

- Machined Hot formed nuts <1.5 in. (38.1 mm) nominal diameter

- Machined Hot formed nuts >1.5 in. (38.1 mm) nominal diameter

- Whitford Xylan™

- Everslik® Coatings

- Zinc Plating

- Zinc-Nickel Plating

Manufactured in accordance with industry standards, including API and ASTM.

Available in various thread forms for compatibility with different equipment types.

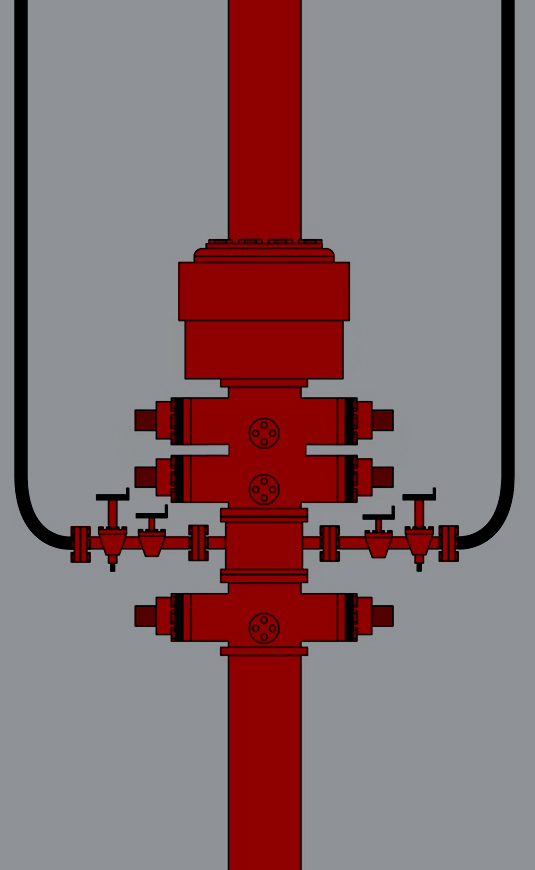

Applications and Use Cases

Studs and Nuts are essential in

Pressure Control Systems

Ensuring secure connections in BOPs and other pressure control equipment.

Pipeline Connections

Providing strong, leak-proof connections in pipelines.

Drilling and Wellhead Equipment

Used in the assembly of drilling and wellhead equipment for secure fastening.

Benefits and Features

Engineered to withstand harsh environments and high-stress applications.

Suitable for a wide range of oilfield equipment.

Rigorously tested to ensure performance and reliability.

Popular Questions

FAQs

Yes, we offer customization options to meet specific application requirements.

Available upon request.

Stock and custom sizes available, with various shipping options.