Windlass Engineers and Services

Windlass Engineers & Services is a vertically integrated manufacturer,

distributor and service provider for the Upstream Oil & Gas industry.

Global Excellence in Manufacturing and Quality Assurance

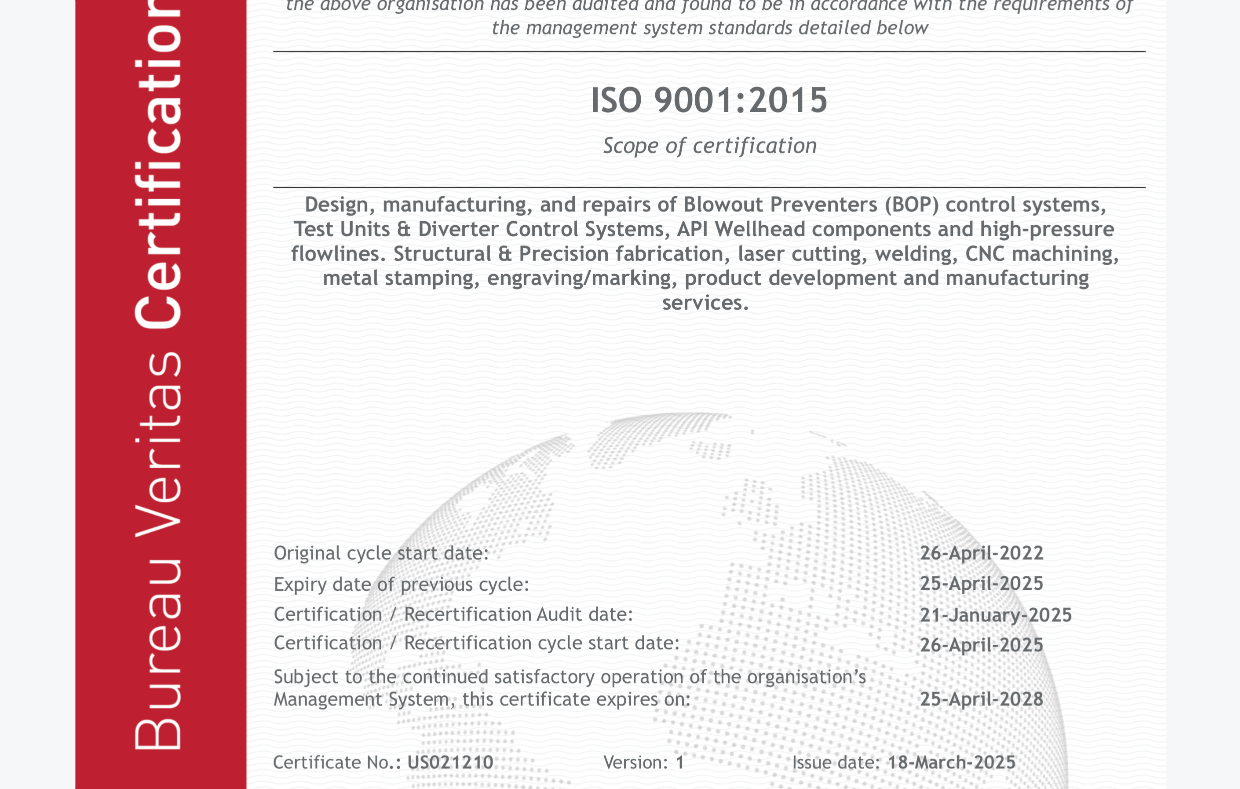

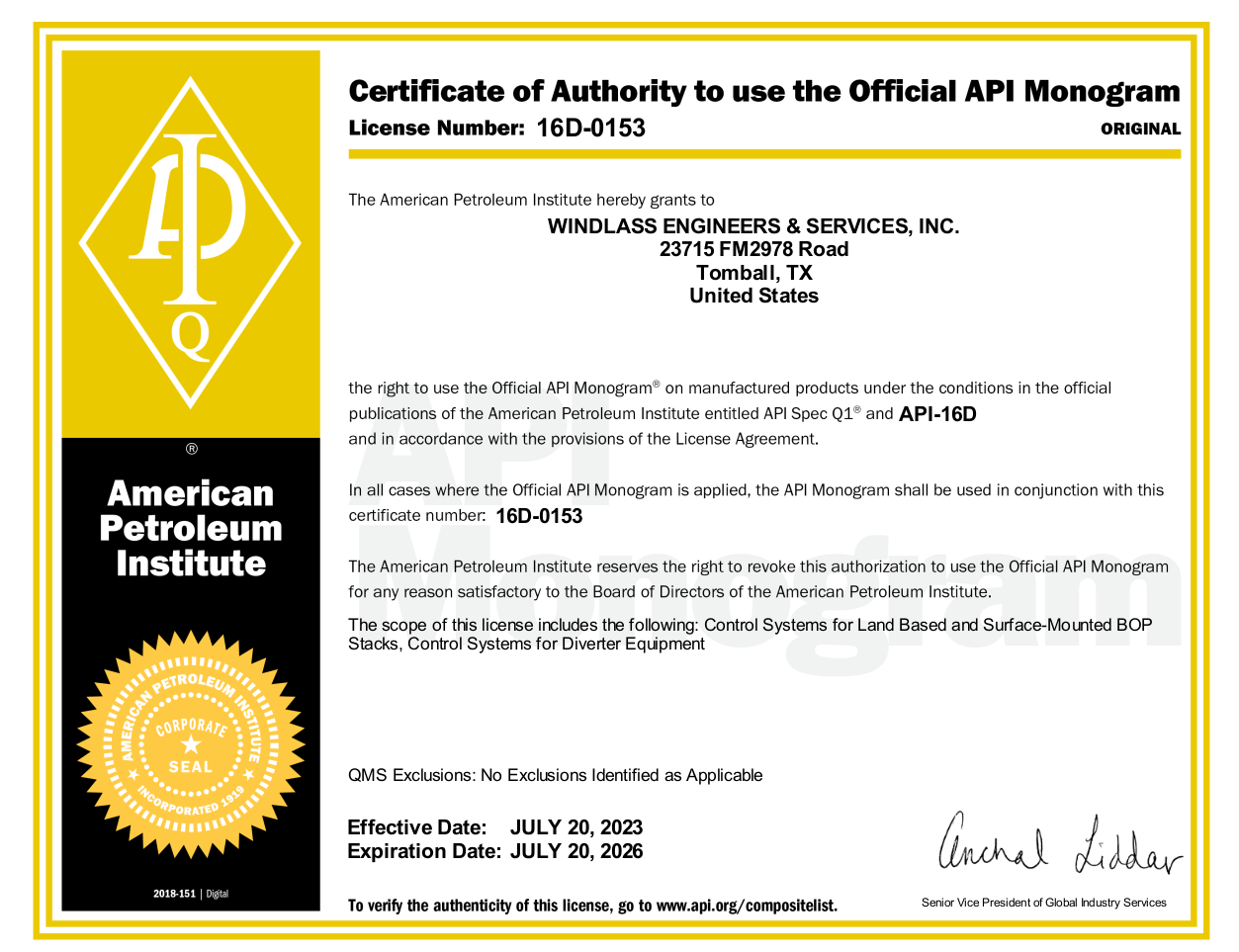

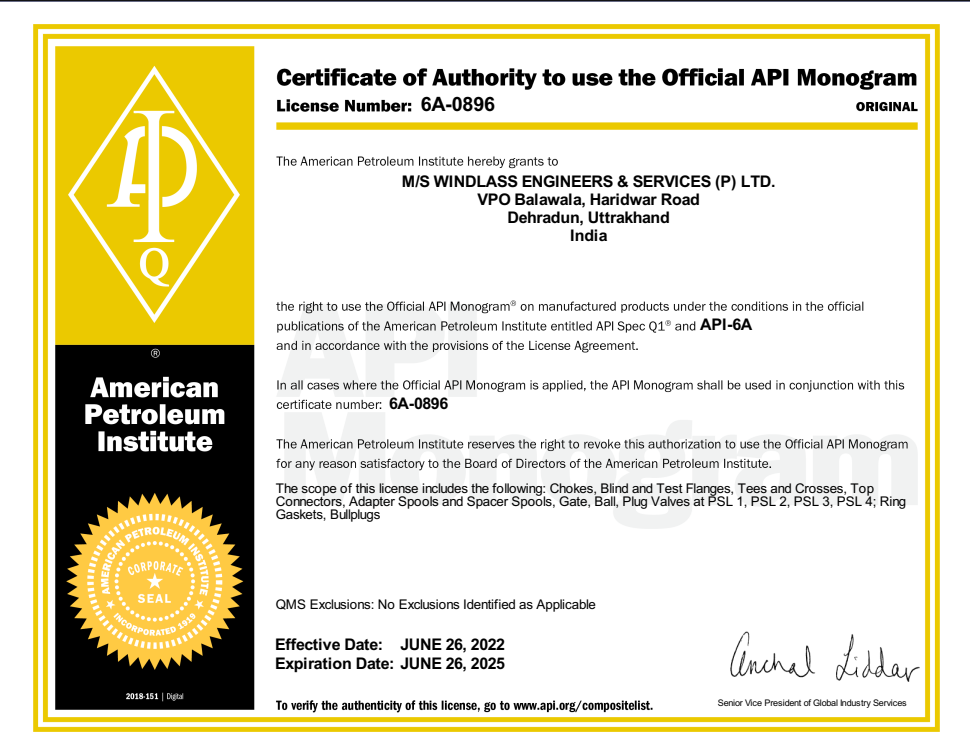

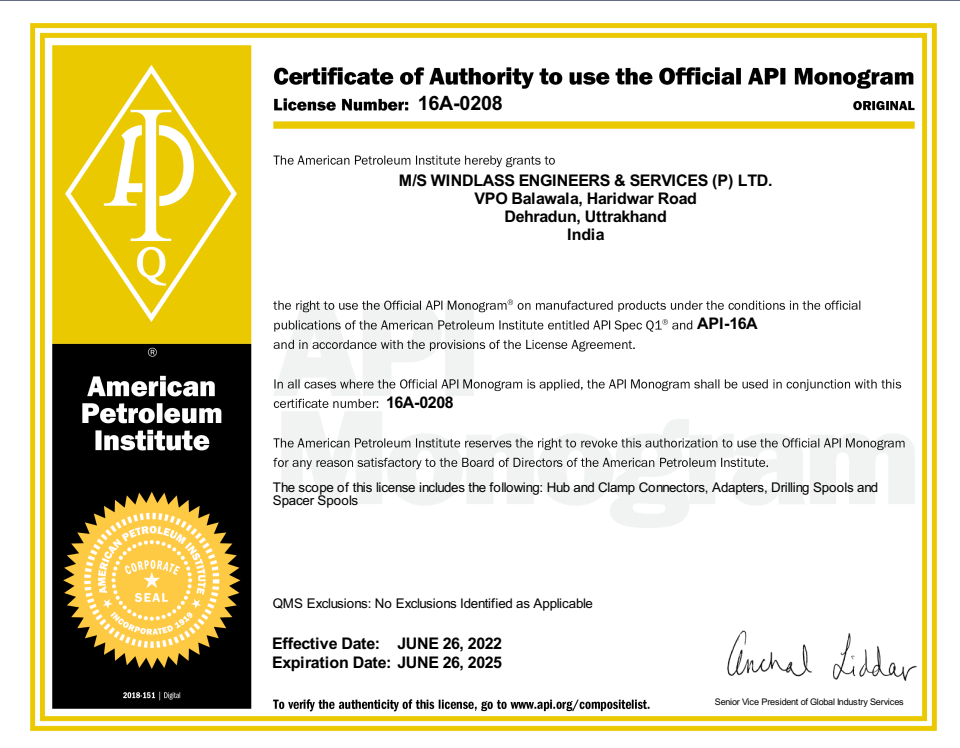

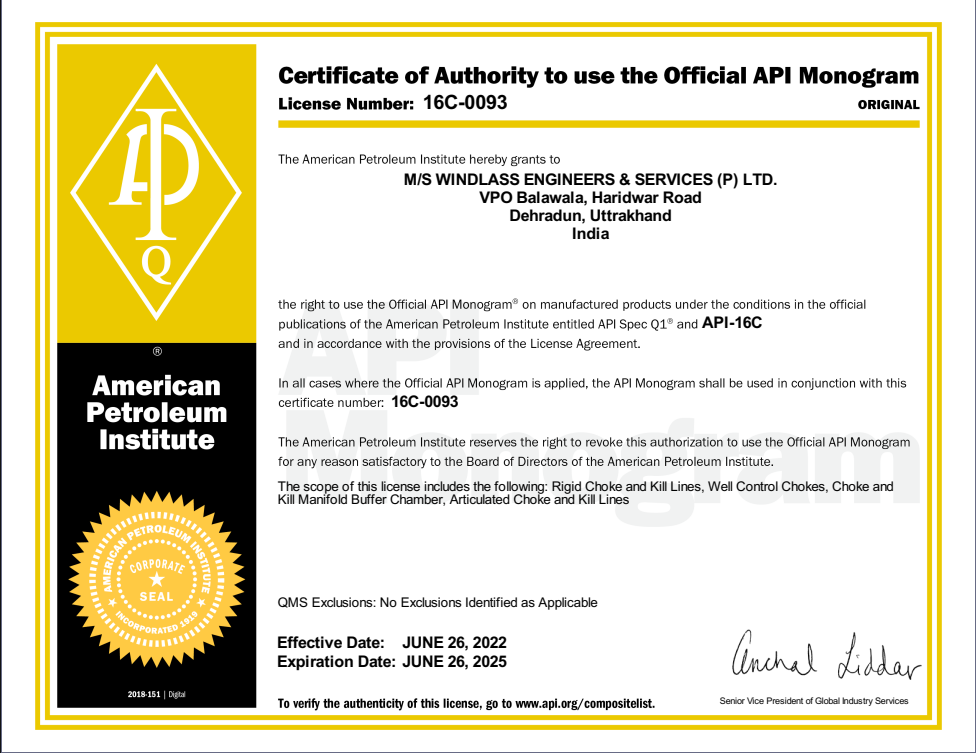

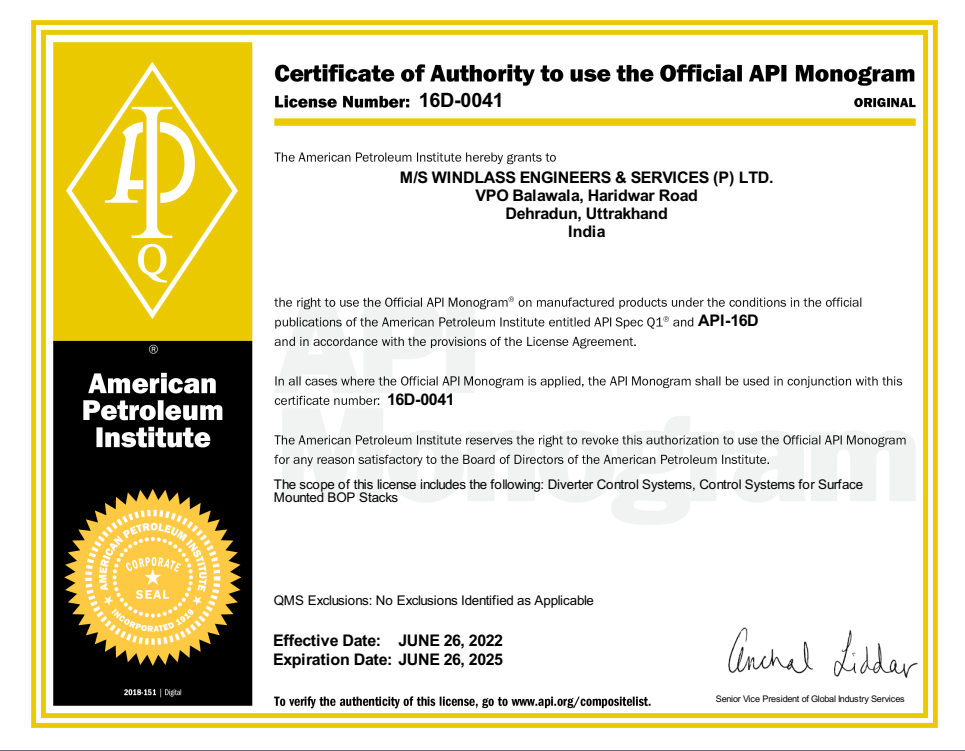

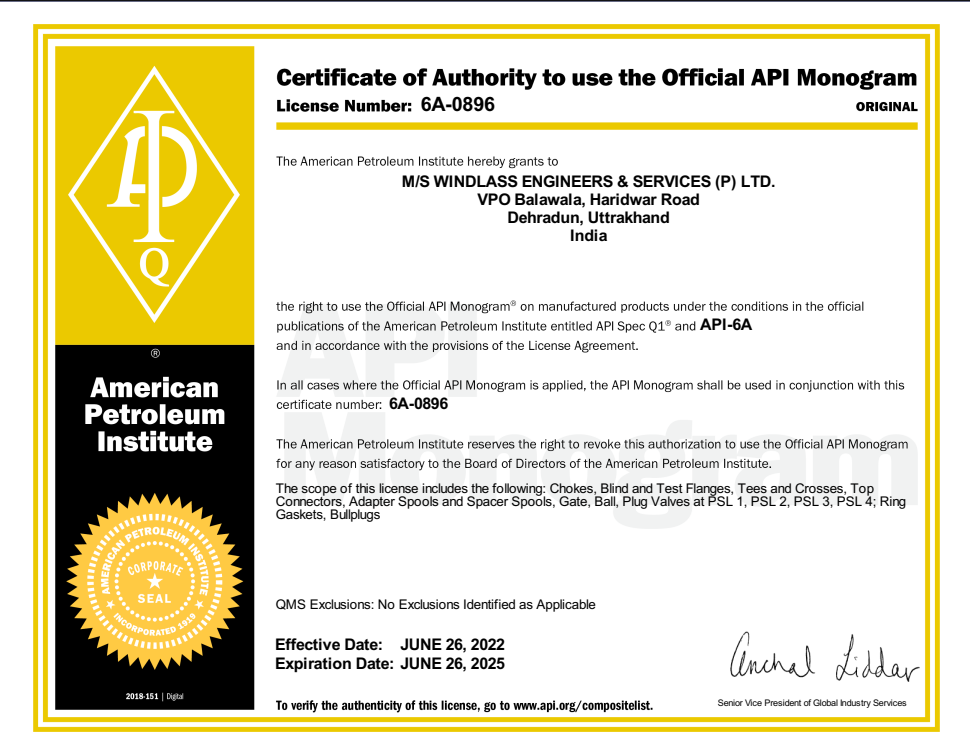

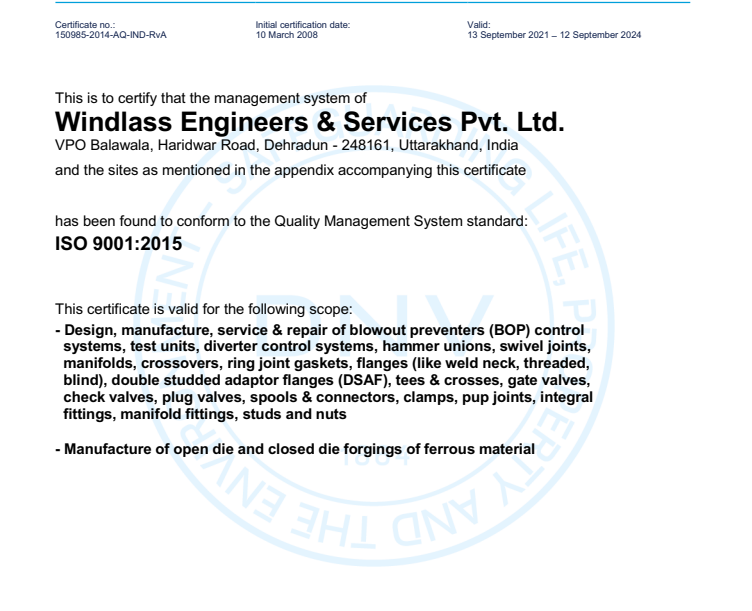

At Windlass Engineers and Services, we are proud to operate full manufacturing facilities in India and Texas, USA, each adhering to a rigorous global quality assurance program. Our comprehensive certifications include ISO-9001:2015, API 6A, API 16A, API 16C, API 16D, API 20E, CE-PED, and ATEX. Our facilities and processes have not only been audited and approved by renowned third-party agencies such as DNV, ABS, and Bureau Veritas, but also by several customer-specific audits from some of the world’s leading manufacturers and Fortune 500 companies. At Windlass, we commit to the highest standards of quality and reliability, ensuring top-tier products and services for our clients globally.

Our Products

Quality Oilfield Equipment

Windlass Engineers & Services is an established manufacturer and distributor of quality oilfield equipment. Our manufacturing facility is spread over 10 acres with manufacturing buildings of 60,000 square feet that house state-of-the-art manufacturing processes manned by a highly qualified, motivated and experienced team.

Windlass BOP Control Systems meet or exceed the most stringent quality standards including American Petroleum Institute specifications API 16D, RP16E & RP53 to assure safe and reliable operation under critical conditions for both onshore and offshore applications.

Windlass manufactures Diverter Control Panels that meet or exceed API 16D requirements.

Hydraulic diverter controls can be supplied in free-standing rig floor panel design with graphic representation.

Windlass manufactures High Pressure Test Units from 5,000 to 30,000 PSI working pressure. These units can be used on site for hydrostatic testing of any product including BOP stacks, kill & choke lines and wellheads.

BOP test stump includes base plates, side and bottom ports and fixed or removable test mandrel retaining threads. We offer a wide variety of test flanges and Blow Out Preventer (BOP) Test stumps suitable for manufacturers test facilities or drillers testing operations.

Windlass offers complete range of Manifold systems for drilling and production applications. Buffer chamber, gate valves, check valves, drilling chokes and actuators incorporated depending on the application and customer requirement.

Electric or diesel powered units designed to provide maximum power output from a compact, rugged and reliable design. Reliable power to cussing, tubing tongs and other applications.

Windlass offers a comprehensive range of standard and sour gas Hammer Unions. Each union is thoroughly inspected to ensure long, dependable service in the most extreme conditions.

Types: Adapter, Spacer Spools & Drilling Spools

Sizes: 1-13/16” to 30”

Pressure Ratings: 2,000 to 20,000 PSI

Inlays: SS & Inconel

Services: Standard & H2S

Constructions: Integral & Welded

Windlass Integral Fitting is a high quality forged construction with wing union end connections and can be combined to suit virtually any installation. All Integral Fittings come with full material traceability.

Custom Development

| Put your product development on the fast track by leveraging Windlass’ experience and infrastructure. Tap into our in-house capabilities and take your idea from concept, to design, to prototype, to final product at a speed you never thought possible. |

Get in Touch with us

we are happy to assist you

- What are your requirements?

- How many do you need?

- When do you need it?