DRILLING BOP CONTROL SYSTEMS

Explore more Products

Get a Free Quote

DRILLING BOP CONTROL SYSTEMS

Windlass BOP Control Systems meet or exceed the most stringent quality standards including American Petroleum Institute specifications API 16D, RP16E & RP53 to assure safe and reliable operation under critical conditions. We provide BOP Control Systems for both onshore and offshore applications worldwide as well as ATEX marked systems.

Our BOP Control Systems are custom designed and manufactured to meet customers’ requirements and certifications.

Our Design department is well equipped with the best tools and software for designing these units and each unit undergoes extensive tests and checks before dispatch to ensure trouble free operation to minimize rig shutdown time and ensure greater safety for the drilling crew.

We can also upgrade and refurbish an obsolete unit as per API 16D or any other similarly recognized standard. All of which are supported by the Windlass field service network of engineers and technicians with extensive knowledge of electrical, hydraulic and pneumatic systems.

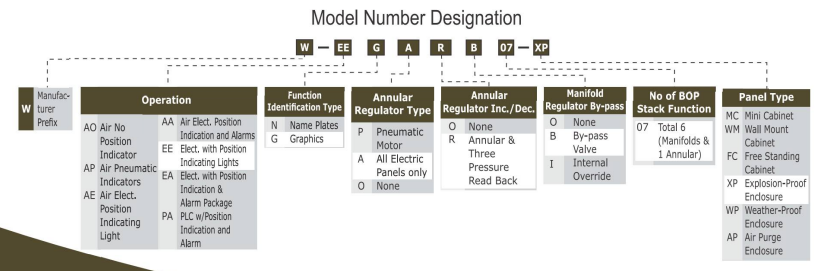

Windlass BOP Control Systems are highly customizable. The following sections describe some of the options available on each subassembly. You can always contact us with your requirements and we can design the entire system for you.

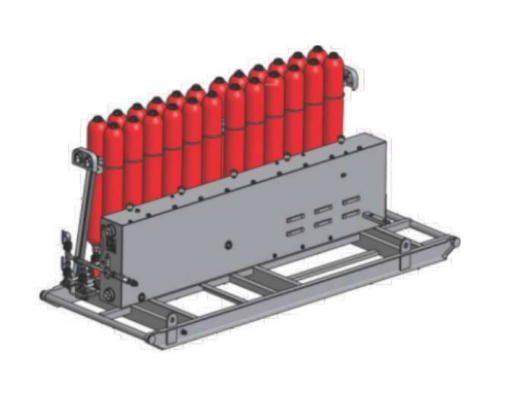

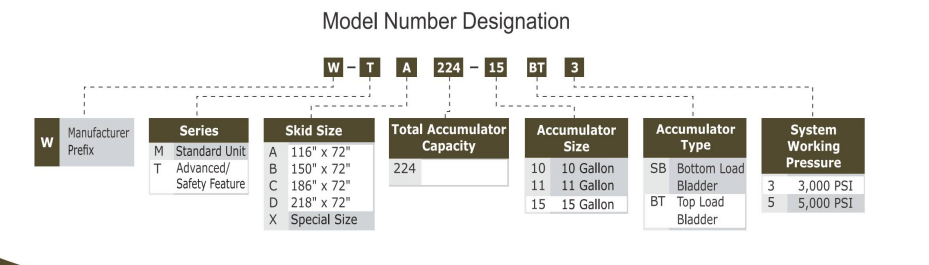

ACCUMULATOR MODULES

The Accumulator Module consists of a welded structural steel skid assembly with a fluid reservoir, provisions for mounting the electric pump, air pump system, hydraulic control manifold, interface module and the type and quantity of accumulators.

M – Series

T – Series

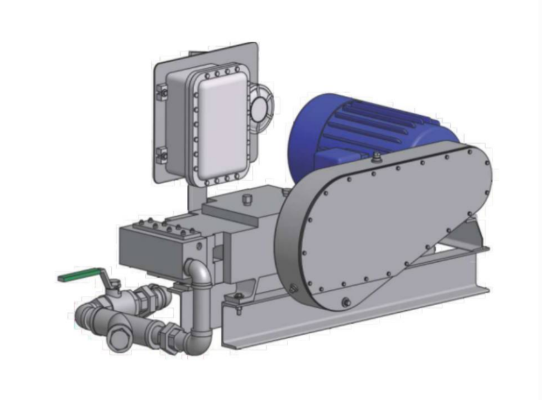

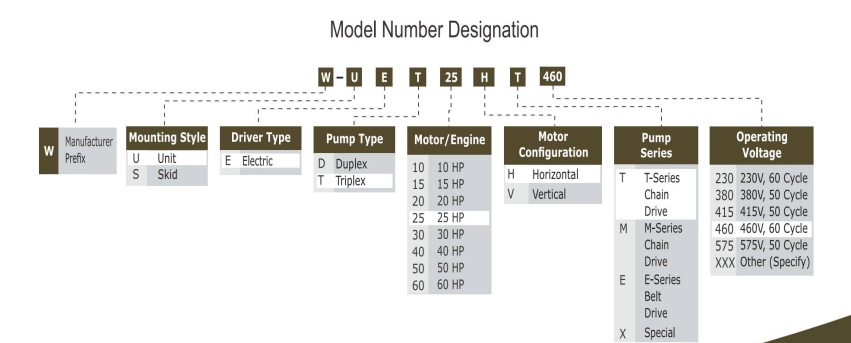

ELECTRIC MOTOR DRIVEN PUMP MODULES

The Electric Motor Driven Pump Module is the primary source for generating hydraulic energy which is stored in the accumulators to operate the BOP stack. These pumps are offered in a variety of options and operating voltages to meet customer requirements.

Type of Modules

T-SERIES

M-SERIES

S-SERIES

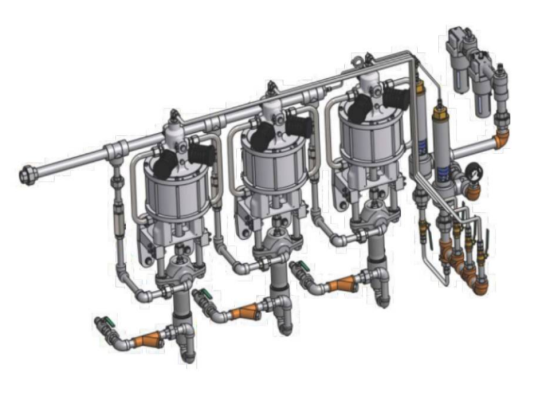

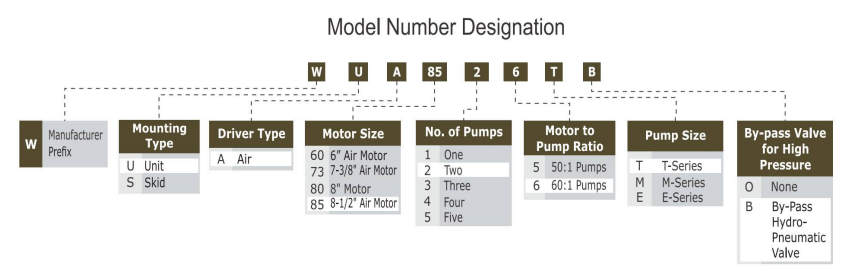

AIR OPERATED PUMP MODULES

Air Operated Pump Module is the Secondary source used to provide high pressure fluid energy to charge the accumulator and operate the BOP stack functions.

Types of Modules

T-SERIES

M-SERIES

E-SERIES

UNIT MOUNTED HYDRAULIC CONTROL MANIFOLD

Types of Modules

T-SERIES

⦿ Sub-plate mounted control valves

⦿ Separate circuits provide independent pressure regulation and control for the annular preventer, ram and HCR valve

⦿ 1 inch full flow controlling annular preventer for up to 36 gallons closing capacity and 1-1/2 inch for over 36 gallons

⦿ The manifold functions are supplied through the 3 inch machined manifold rated for 3,000 PSI or 5,000 PSI working

pressure

⦿ The internal override feature of the regulator permits immediate working accumulator pressure to the manifold, doubling

the closing force on the rams in an emergency

⦿ The manifold directional control valves and outlet piping to the preventers are rated for 3,000 PSI or 5,000 PSI working

pressure

⦿ These manifolds are available with glycerin-filled, panel-mounted, direct reading gauges indicating manifold regulated,

annular regulated and accumulator pressures

⦿ When hydro-pneumatic valve by-passes are selected in the air pump assemblies, this series manifold can be used for

testing up to 5,000 PSI and extreme well control problems

M-SERIES

E-SERIES

REMOTE CONTROL PANELS

Located at a safe distance from the rig floor to ease space restrictions and increase safety, Remote Control Panels give the driller complete control of the BOP stack and provide intuitive operation of the BOP Control System with its hydraulic control manifold.

Types of Modules

DRILLER REMOTE PANEL

AUXILIARY REMOTE PANEL

At least one Remote Control Panel is required in order to comply with AP116 D, RP53, API- RP-16E.

Remote Panels used for offshore installations must have meters to indicate pressure, alarm indicators and position status indication at the driller’s position.

Types of Remote Control Panels

AIR REMOTE PANEL

ELECTRIC REMOTE PANEL

PLC REMOTE PANEL

• Low accumulator pressure

• Low rig air pressure

• Low hydraulic fluid reservoir level

• Panel on standby power

• Accumulator pressure

• Manifold regulated pressure

• Annular BOP regulated pressure

• Rig air pressure

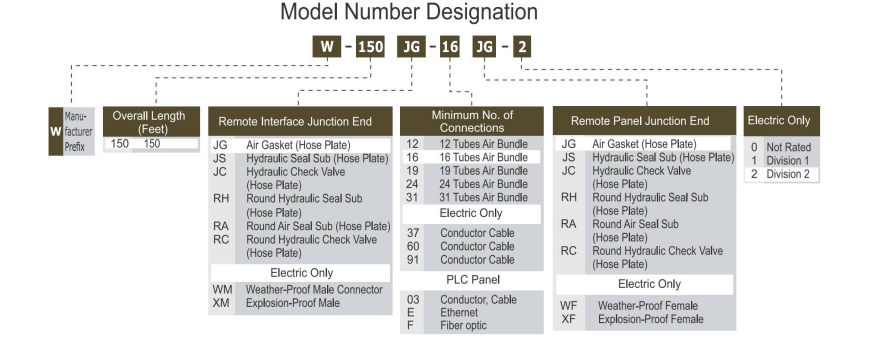

INTERCONNECT CABLE ASSEMBLIES