Explore more Products

Get a Free Quote

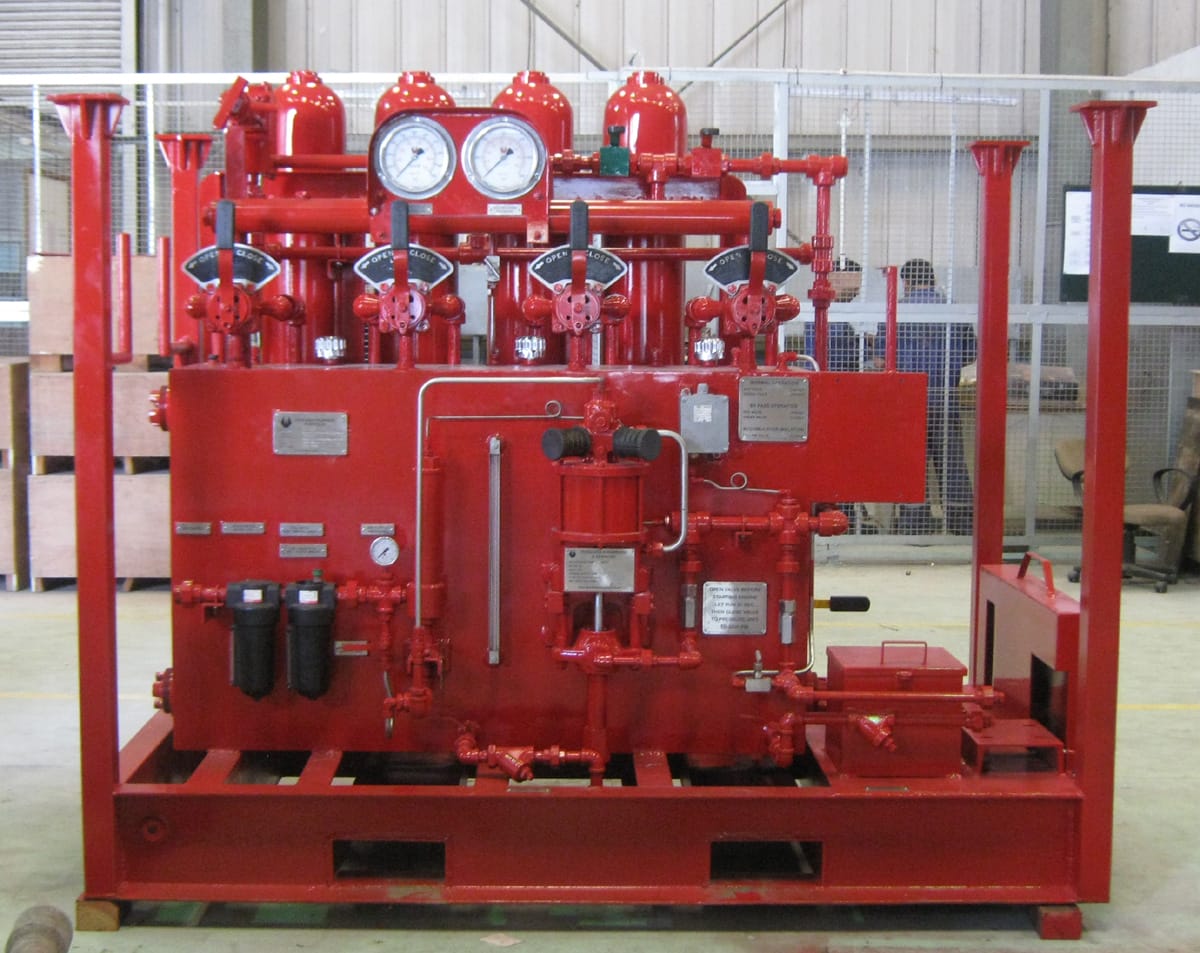

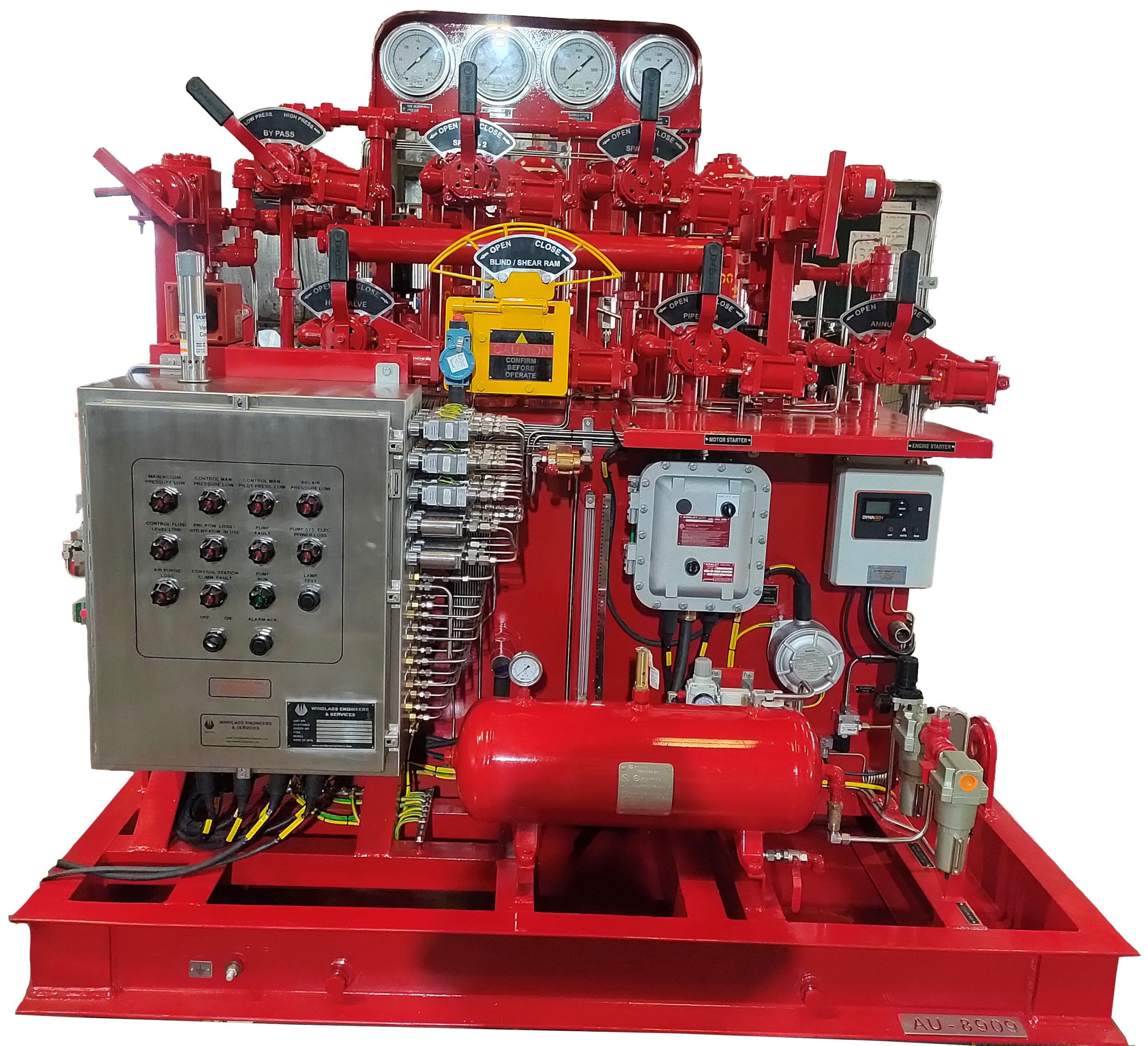

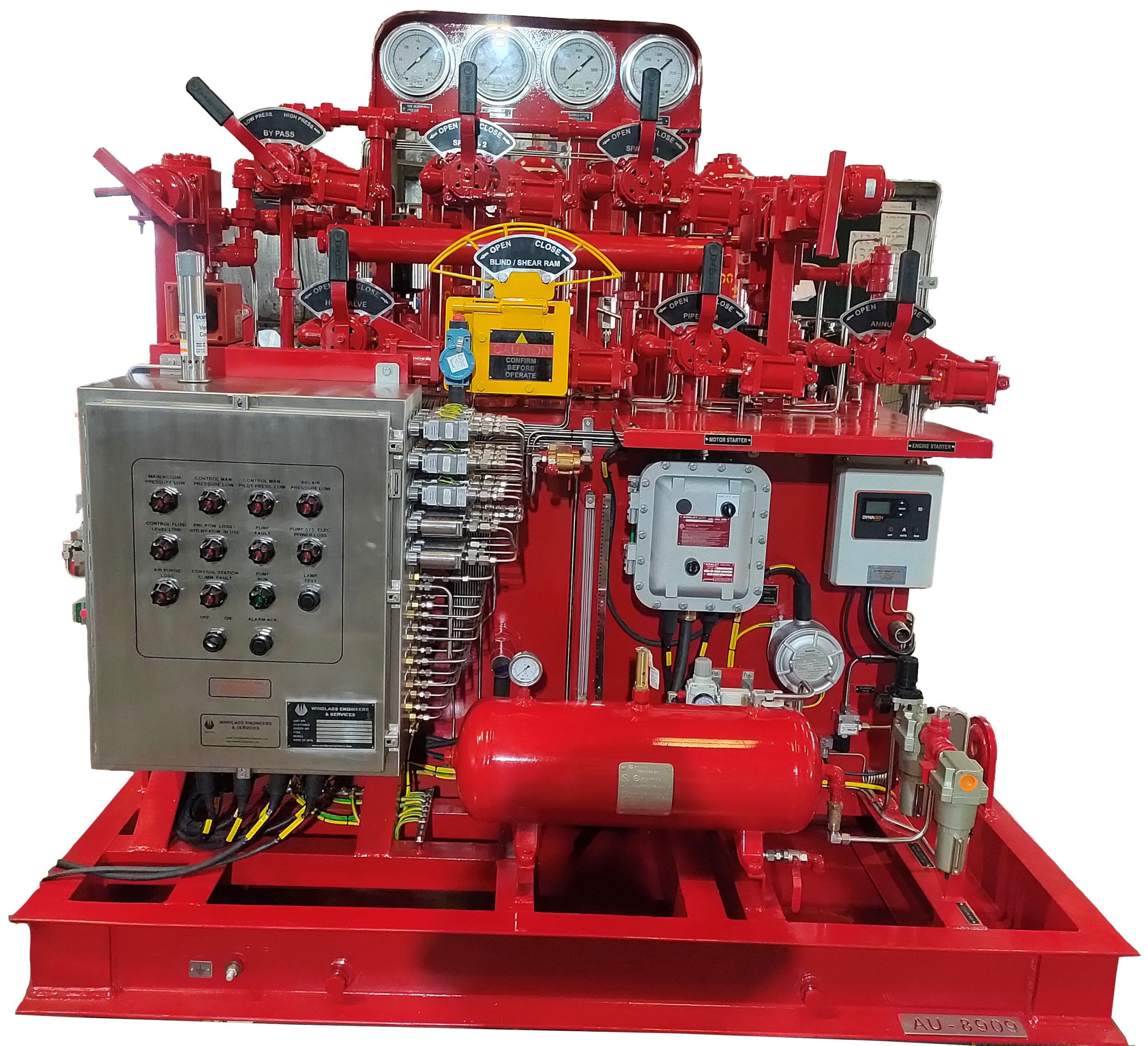

DRILLING BOP CONTROL SYSTEMS

Windlass BOP Control Systems meet or exceed the most stringent quality standards including American Petroleum Institute specifications API 16D, RP16E & RP53 to assure safe and reliable operation under critical conditions. We provide BOP Control Systems for both onshore and offshore applications worldwide as well as ATEX marked systems.

Our BOP Control Systems are custom designed and manufactured to meet customers’ requirements and certifications.

Our Design department is well equipped with the best tools and software for designing these units and each unit undergoes extensive tests and checks before dispatch to ensure trouble free operation to minimize rig shutdown time and ensure greater safety for the drilling crew.

We can also upgrade and refurbish an obsolete unit as per API 16D or any other similarly recognized standard. All of which are supported by the Windlass field service network of engineers and technicians with extensive knowledge of electrical, hydraulic and pneumatic systems.

Windlass BOP Control Systems are highly customizable. The following sections describe some of the options available on each subassembly. You can always contact us with your requirements and we can design the entire system for you.

ACCUMULATOR MODULES

The Accumulator Module consists of a welded structural steel skid assembly with a fluid reservoir, provisions for mounting the electric pump, air pump system, hydraulic control manifold, interface module and the type and quantity of accumulators.

M- Series

The M-Series Accumulator Module has standard features and is a quality economical choice

T- Series

The T-Series Accumulator Module has advanced safety features and is additionally equipped with a reservoir level sight gauge and 14 inch x 14 inch clean-out man-way for reservoir maintenance

ELECTRIC MOTOR DRIVEN PUMP MODULES

The Electric Motor Driven Pump Module is the primary source for generating hydraulic energy which is stored in the accumulators to operate the BOP stack. These pumps are offered in a variety of options and operating voltages to meet customer requirements.

Standard Electric Pump Module is designed for operation in hazardous locations where the presence of explosive gases is anticipated and includes automatic electric explosion-proof starters, motors and pressure switches. Electrical components that meet NEMA, NEC and UL specifications are standard in these modules

The Electric Pump Module is set to automatically stop when system reaches working pressure and restart when system pressure drops to 10% below working pressure

Each Electric Pump Module is sized to meet the greater of the following two conditions:

Close the specific annular preventer in use and open the hydraulic-actuated choke valve within two minutes (with the accumulators blocked)

Charge the accumulators from zero to working pressure in less than fifteen minutes

M- Series

This pump module has the same features as the T-Series but is limited to 20 Horsepower by plunger load design specifications

S- Series

This pump module has the same features as T-Series but comes with a special drive

T- Series

The T-Series Electric Driven Pump has a triplex plunger

■ The electric motor is horizontally mounted but can be vertically mounted over the pump in order to meet the length restrictions

■ The motor is mechanically coupled to the pump drive by a rugged chain and sprocket drive assembly specifically designed for the working horsepower of the assembly

■ The drive assembly is encased in an oil bath protective guard to ensure years of hassle-free operation