Windlass Modular Frac Accumulator System

- Products

- Control Systems & Panels

- Windlass Modular Frac Accumulator System

Windlass Modular Frac Accumulator System

Efficient and Reliable Frac Valve Actuation Solution

- Overview

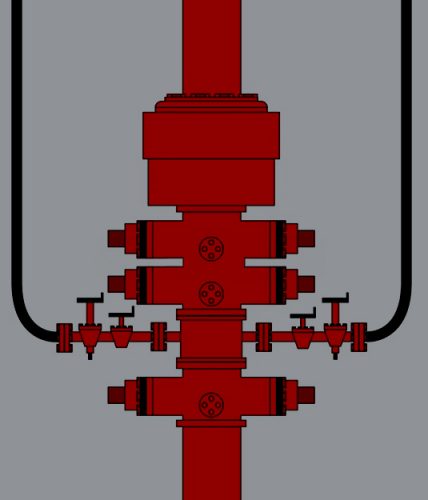

Our Modular Frac Accumulator System offers a highly efficient solution for frac valve actuation that surpasses traditional HPU systems. This field-proven system significantly reduces the Total Cost of Ownership, providing a superior and streamlined product. Known as the CHPU/POD system, it features a single central power unit (CHPU) that powers each individual Remote-Control Panel (POD), substantially lowering the carbon footprint.

Technical Specifications

- Engine: Hatz diesel engine with backup air pumps

- Power: Solar-powered panel with battery

- Control: Auto-Start/OFF Smart control panel

- Design: Bent plate style skid

- Gearbox: 2:1 ratio gear box to replace the belt drive, eliminating daily belt torque adjustments

- Capacity: Each POD can actuate up to 6 hydraulic valves

- Control: Dedicated pressure regulator for individual POD pressure control

Each POD maintains its own stored energy for quick fluid propulsion and reduced actuation time

Closed-loop system providing redundancy

Design Comparison

Traditional HPU Set-up

CHPU/POD Set-up

Applications and Use Cases

The Modular Frac Accumulator System is ideal for

Frac Valve Actuation

Providing precise control and efficient actuation in hydraulic fracturing operations

Oil and Gas Industry

Enhancing operational efficiency and reliability in frac pads

Benefits and Features

Generates, stores, and provides hydraulic pressure to the PODs, enhancing efficiency and reducing the environmental impact.

Eliminates the need for daily belt torque adjustments, reducing downtime and maintenance costs.

Ensures quick fluid propulsion into the actuator, minimizing actuation time.

Enhances reliability with a closed-loop system.

Designated POD per well prevents accidental shut-ins or actuations.

Lower maintenance costs and reduced carbon footprint with one CHPU per frac pad hook-up.

Available in both hydraulic and PLC modes for versatile operation.

Popular Questions

FAQs

Each POD can actuate up to 6 hydraulic valves.

Available upon request.

Please contact us for stock availability and custom orders.

These setups are favored for their durability and cost-efficiency across various sectors, with hydraulic fracturing (frac) being a primary application.

Yes, daisy chaining allows multiple Pods to share fluid and pressure in series. This is a key feature of the Windlass CHPU and POD configuration.

Each POD is equipped with isolation and bleed valves, enabling service without disrupting the daisy chain.

Absolutely. Engine RPM can be manually adjusted via the controller's front panel or programmed as needed.